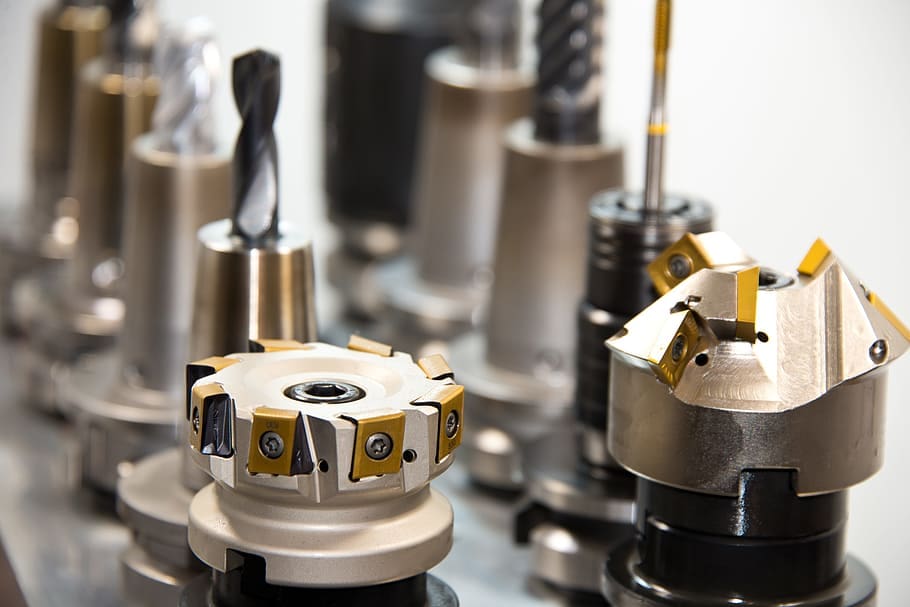

CNC Machining produces high-quality, precision-machined items that are tailored to your needs.

We deal with a wide range of clients, from the initial concept to the final result. We are experts in high-precision design and machining from the ground up. To properly program your parts for production, our team employs industry-standard MasterCam software. Titan Metal Products, LLC continues to build for the future by using the most up-to-date computer-aided manufacturing technology. This enables our personnel to program simple to complicated machine components using engineering data, downloads code straight to our CNC lathes and CNC Machining centers, and provide better service and quality to our clients. We value customer service since no one wants miscommunication or mistakes in the fabrication of components for any sector.

- CAD/CAM Design

- Custom Built Fixtures

- CNC Milling

- YAMA-SEIKI MACHINING CENTER: Travel – X55” Y24” Z24”

- KITAMURA MYCENTER 4 CNC MILL: Travel – X44” Y22” Z22”

- FADAL VMC 3016L CNC MILL: Travel – X30” Y16” Z16”

- 4 – PROTOTRAK CNC VERTICAL MILLS: Travel – X32” Y16” Z16”

- CNC Turning

- MAZAK QT NEXUS 250 II CNC LATHE: 24” DIA X 18.73” LENGTH

- CUTMASTER LATHE: 22” DIA X 120” LENGTH

- Material Handling

- SAW CAPABILITIES: 9” X 16”

- FORKLIFT CAPABILITIES: 4000 LBS