CNC Machine Shop from Prototype to Production

serving all of central Ohio and more.

35+ years of CNC Machining Expertise.

Titan Metal Products, LLC was founded in 2013 by Dan Neimeister. We are a full-service CNC and manual shop located in Plain City, Ohio. We have the experience and equipment to accomplish a wide range of machining operations. Titan Metal Products provides 35+ years of machining experience. We operate in a small shop environment, which allows us to provide our customers with the personalized attention and service they require. We specialize in prototype work, low quantity as well as high production runs. Our goal is to provide customers with high-quality machining at a fair price. Titan Metal Products strives to maintain industry standards in order to provide quality work for all customers.

Titan Metal Products, LLC pioneers and discovers cost-effective procedures and solutions for the highest accuracy in precision and quality for all of our clients’ machining demands, based on our combined industry experience. When selecting a CNC Machine Shop to build your prototype or plan your idea for a final product, seek the experience. Whatever your CNC machining requirements are, we have the expertise to ensure the highest level of accuracy and quality. Our area of expertise spans a variety of industries but our main focus is the following:

- Automotive

- Specialty Tool

- Government

- Food Industry

- Medical Industry

We maintain our prices as low as possible while keeping a high level of efficiency and quality. Titan Metal Products, LLC has worked with a variety of clients throughout Ohio for decades. Modern machine shops must keep up with technology improvements that save costs and increase quality. These have to do with maintaining tight tolerances during the milling and turning processes. We are convinced that our skilled machinist will manage your manufacturing project with the utmost professionalism. Please contact us by phone, email, or in person to discuss your CNC manufactured components’ specific requirements. Visit us at Plain City, Ohio, where we proudly service the greater Columbus area.

What can Titan Metals Products, LLC do for you?

- We are motivated by your requirements. Each employee is responsible for focusing on your needs and doing everything possible to meet or exceed them.

- Commitment to Integrity and High Ethical Standards – We operate our business with a high standard of behavior at all levels.

- People – We strive to provide a safe, healthy, and harassment-free workplace where everyone has the opportunity to learn new skills and apply what they’ve learned.

- Community – Our goal is to create the desired workplace that is recognized as a dependable and valued economic asset in the community.

- Continuous Improvement – We work hard to continually improve our operations, quality assurance, and workplace organization.

- As a result of these values, you will receive the Value, Quality, and Turnaround that you require. We guarantee that working with Titan Metal Products, LLC will save you time, money, and effort.

The Materials we work with and our CNC Machining Capabilities.

Our team of skilled machinists and programmers can design a manufacturing process for any sort of machining operation, and we’ve worked with a variety of materials, including:

- All Carbon Steels

- Alloy Steels

- Tool Steels

- All types of Stainless Steel

- All Grades of Aluminum

- All Plastics

Our CNC machines can accomplish your assignment in a timely manner while still staying within budget.

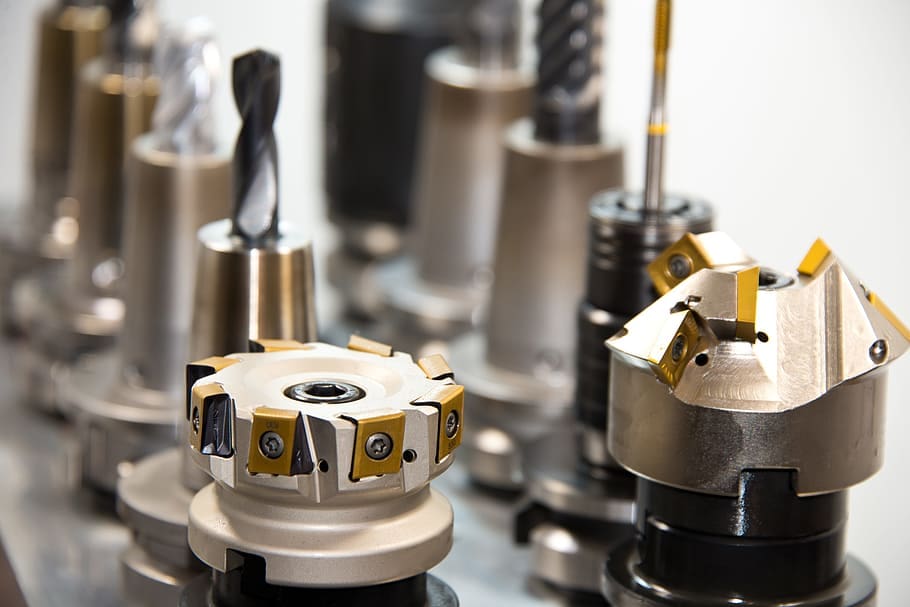

CNC Machining

- YAMA-SEIKI MACHINING CENTER

- KITAMURA MYCENTER 4 CNC MILL

- FADAL VMC 3016L CNC MILL

- PROTOTRAK CNC VERTICAL MILLS

- MAZAK QT NEXUS 250 II CNC LATHE

Machining Capabilities

- CAD/CAM Design

- Custom Built Fixtures

- CNC Milling

- CNC Turning

- Material Handling

Machining Materials

- Aluminum

- Steel

- Stainless Steel

- Tool Steels

- Plastics

Titan Metals Products, LLC. Quality Control (QC).

The term “quality control” refers to a thorough examination of products and production processes. Quality control is critical in CNC processing to ensure that the finished products fulfill the norms and criteria of businesses, industries, and customers. Furthermore, proper CNC component quality control will eliminate defective products, decrease risks, ensure dimensional correctness and quality, save resources, lower costs, and increase efficiency. Both manufacturers and buyers benefit from this.

We chose CNC machining at Titan Metal Products, LLC because it has various advantages. Quality inspection is and will always be a top emphasis in our manufacturing process, even if CNC machining can provide higher productivity and fewer errors than traditional machining. All stages of our machining process are subjected to quality control and inspection.

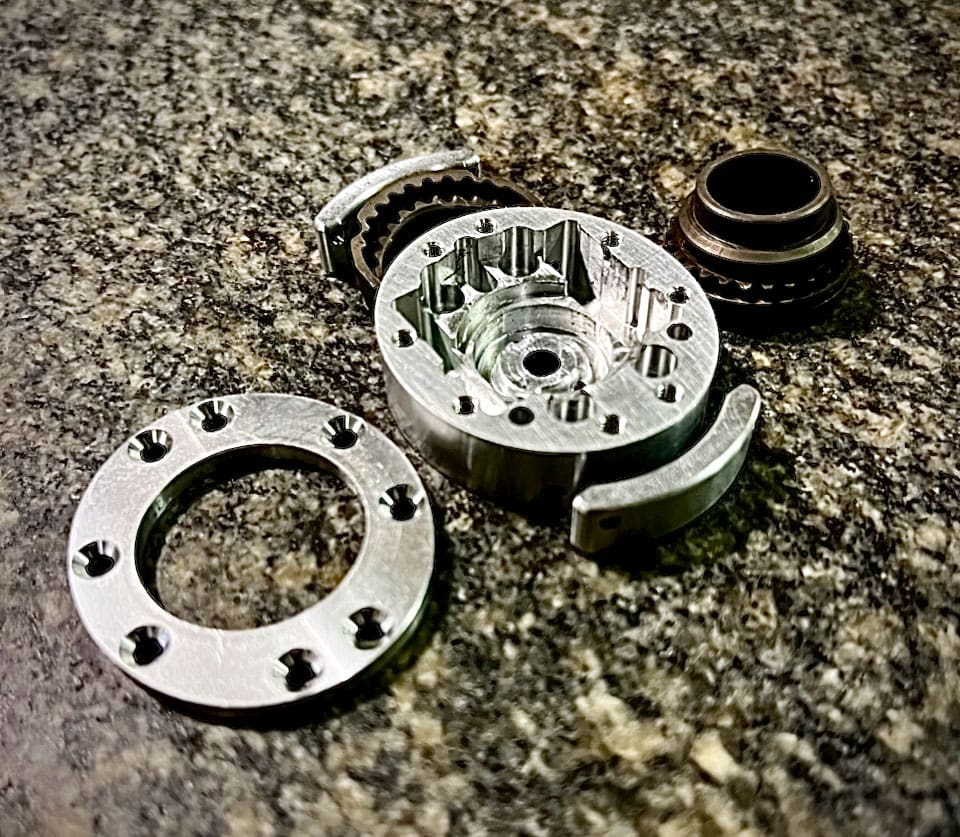

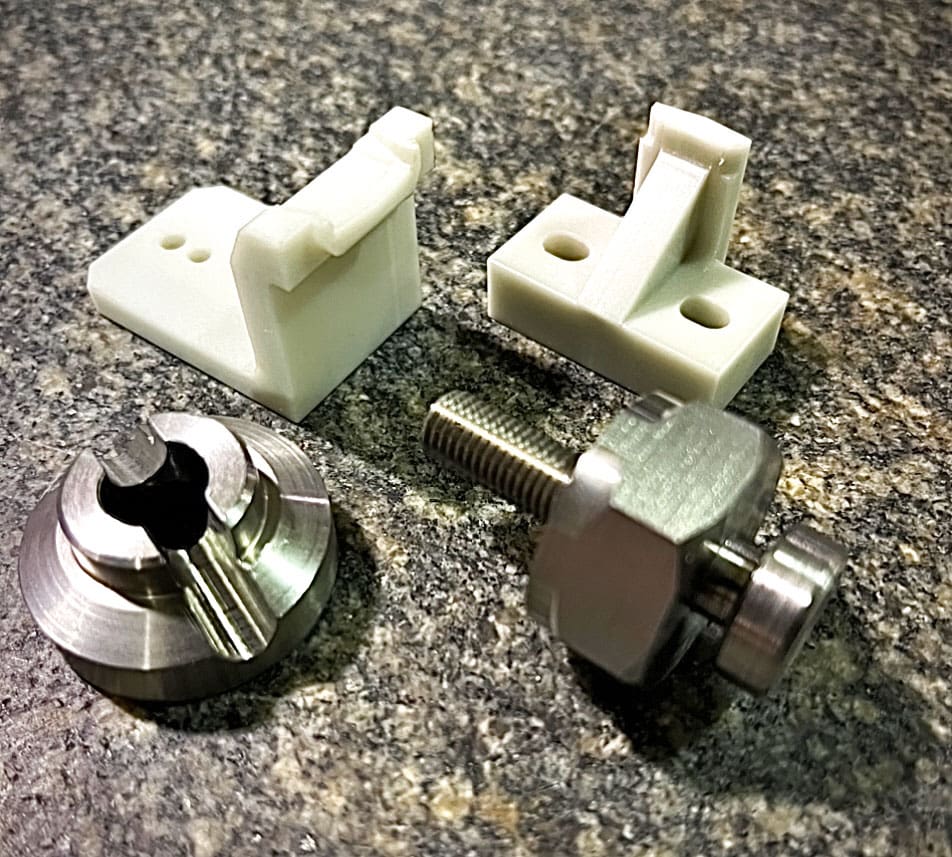

Sample of our Work.